Seaweed Inspired, 3D Printed Metal Bottle Opener

Tweet

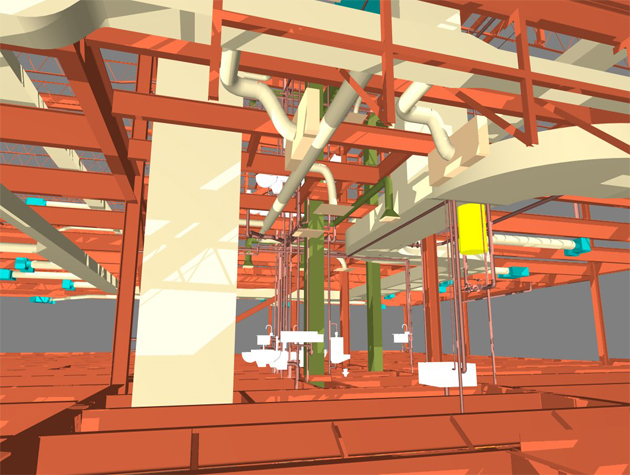

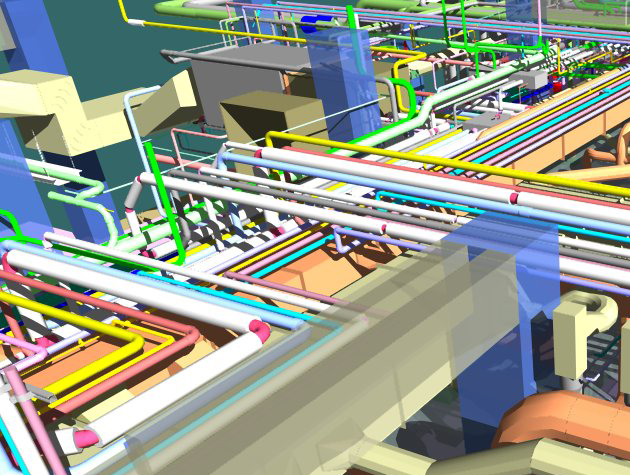

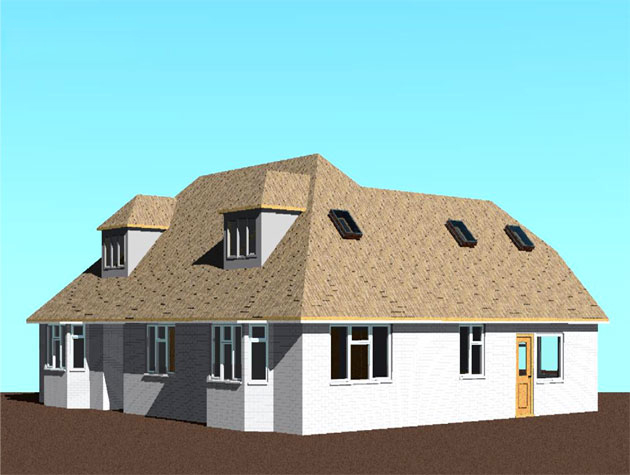

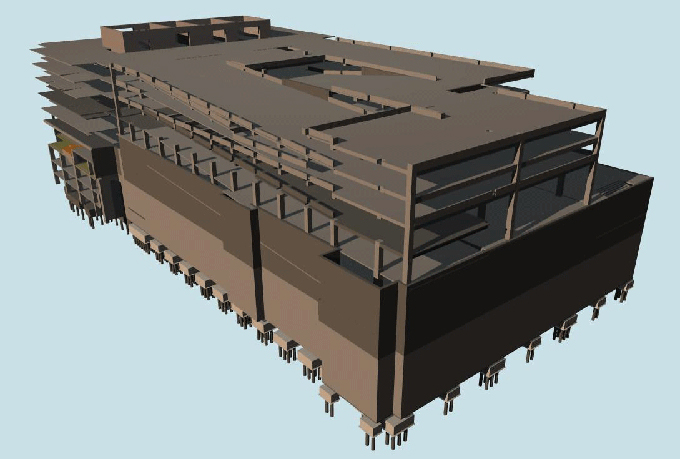

Autodesk Inc. is an American multinational software corporation which creates software for the architecture, engineering, construction, manufacturing, media and entertainment industries and become a leader in 3D design.

After its establishment in the industry, it is developing itself continuously about the widest summary for global markets and there is huge number of customers from the manufacturing, architecture, building, construction, media and entertainment industries that are satisfy with their software using it for designing, visualizing and simulating their ideas before any kind of creation.

Autodesk is very popular and best known for AutoCAD but it also developing big range o software for every creative field as well as a line of software for consumers such as Sketchbook, Homestyler and Pixlr. They are also creating some educational version of its software with no cost for qualified students and staff through Autodesk Education Community. They also have some digital prototyping software such as Autodesk Inventor, Fusion 360 and the Autodesk Product Design Suite which are used in the manufacturing industry for visualizing, simulating and analyzing real-world showing a digital model in the design process. Autodesk apps can be used in the iPhone, iPad, iPod and Android and the company continuously more accessible design technology for both professional and new designers, homeowners, students and casual creators whoever wants to make and share their ideas with the outer world.

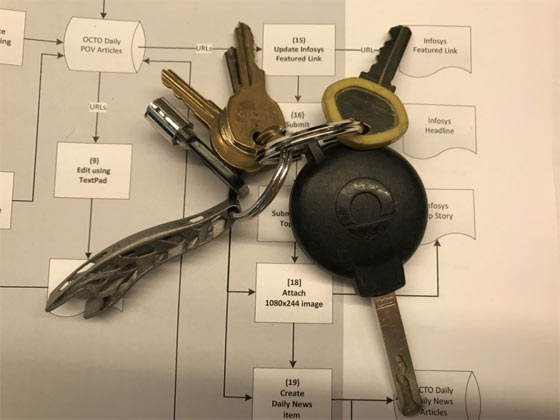

Brand Partnerships Manager, Liz Nugent has recently shared a story about a seaweed-influenced 3D printed metal bottle opener.

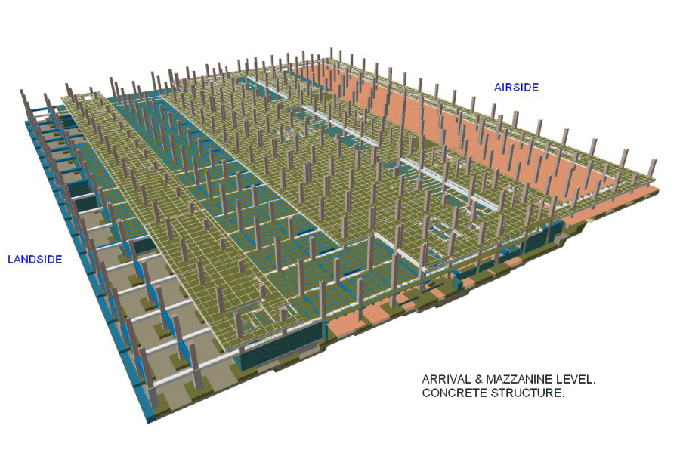

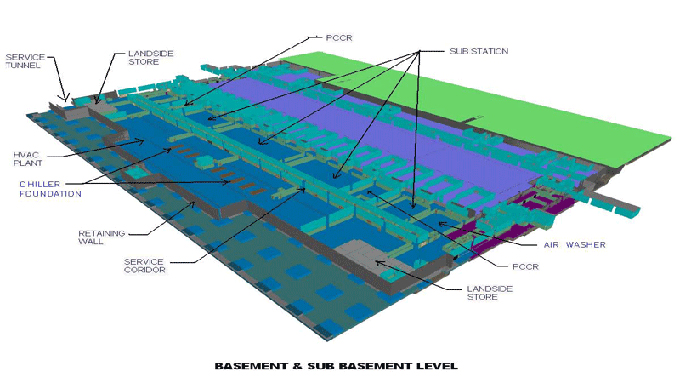

The story behind making a seaweed-based 3D printed metal bottle opener: Autodesk Designer Andriy Banadyga has shared that the original motivation of a 3D printed bottle opener has come from an underwater photo of seaweed. The living structures are replicated through Digital Tools and Future of Making Things workflows and the design has started to grow up in 3DS Max with titanium which is the original building material.

Then the design was exported from 3DS Max and imported into Fusion 360 where the final assemblage and Finite Element Analysis simulation has done. Titanium is used as a material here as it is the only option for highly technical Aerospace and Automotive designs though it is expensively beautiful. But as this bottle opener may or may not be used in Space, so another Autodesk Designer Michael Sagan has examined a redesign with 3D printed-steel by using Fusion 3D and generative design.

The design has started with a bottle and a cap as mentioned points and Sagan rushed dozens of simulations into Autodesk generative design technology with the help of Principal Research Scientist Andres Bastian and Design Engineer Daniele Grandi. They both are experts in the matter of materials and generative design in the Office of the CTO. Matt Lemay, the Additive Manufacturing Expert has also united with Sagan and they both used the Fusion 360 model and NetFabb and prepared the model for Additive Metal Printing. The new steel design of the seaweed inspired bottle opener got a 2X cost diminution over the titanium design.

Here is the little description of the things used to make this bottle opener:

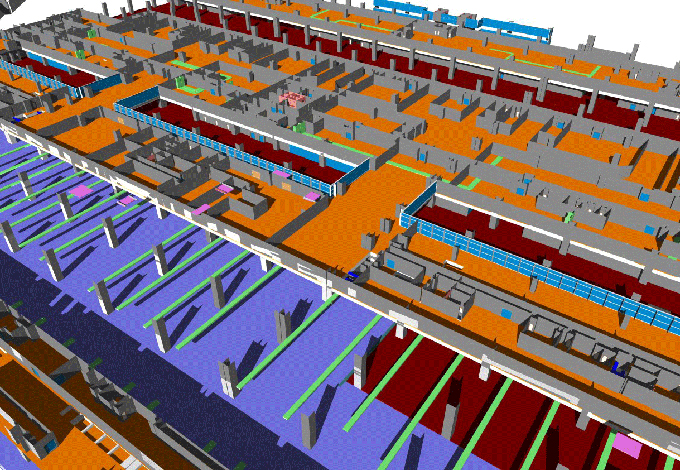

- The Future of Making Things: The manufacturing industry is changing too fast and products are being designed, made and used in different ways and at Autodesk, they offer solutions for all of these including the latest manufacturing technology trends.

- Generative Design: It is a software technology which allows the users to create highly improved designs that complete fixed goals and restrictions. Shape synthesis algorithms and multiphysics performance analysis are used I the cloud, the software produces thousands of design options that can't get easily.

- 3DS MAX: 3ds Max® is a 3D modeling and rendering software that helps user to make huge word games, astonishing scenes for design visualization and engaging virtual reality experiences. It is an easy and robust modeling as it can create, shape and define a range of environments and detailed characters; this software is compatible to work with most major renders like Arnold, V-Ray and Iray. Revit, Inventor, SketchUp, Unity and Unreal each and every software works with 3ds Max.

- Fusion 360: Fusion 360TM is the first ever 3D CAD, CAM and CAE tool of its kind; it also connects with the whole product development that works on both Mac and PC. It also quickly repeat on design ideas with sculpting tools for exploring form and modeling tools to create finishing features; has test fit and motion, perform simulations, can create assemblies, makes photorealistic renderings and animations. Also create toolpaths to device the components or uses the 3D printing workflow to create a prototype.

- NetFabb: It is easy to start and users can download a free 30 days trail and there are many purchase options including flexible subscription terms as per the needs.

For more information, visit labs.blogs.com

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !