CAD Modeling & Prototyping for the Aerospace Industry

Tweet

For test pilots, real world testing remains indispensable in addition to CAD. It is possible to simulate aerodynamics, passenger capacity, power, and fuel efficiency with accurate results using finite element analysis services, but it is the test pilot's responsibility to assess the onboard system and maneuverability.

There are some generic steps in developing an aerospace product that remain the same across industries. A preliminary digital design is built in almost all scenarios in aerospace engineering. They refine and select the most technically feasible model to develop further after a refinement and selection phase.

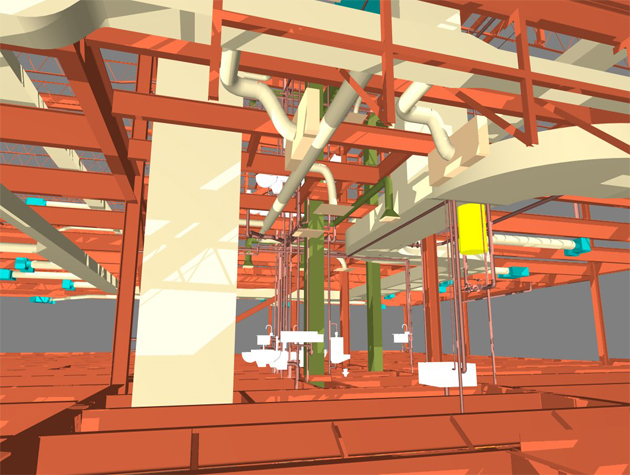

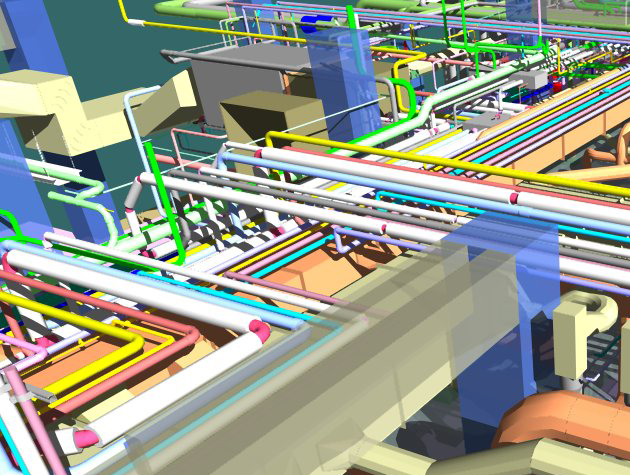

Modeling

In many 3D modeling design companies, the real work begins with designing the aircraft's parts and subsystems using parametric modeling. An aircraft presents enormous complexity, even though it may sound simple in a small mechanical vehicle.

Aero-planes have approximately three million parts and miles of wiring for onboard computers. Parts can resemble their physical shapes, but they also have real life behaviors when they are modeled parametrically. The data set includes weights, material characteristics, and tensile part strengths. The attributes of the parts are derived from surface and solid modeling techniques.

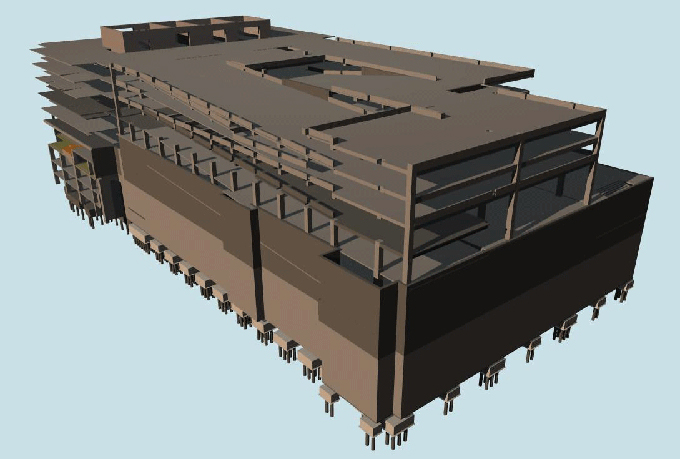

Prototyping

It is almost always the case in the aerospace industry that a prototype represents a fully functional product. The cost of building multiple aircraft test models is not worth the effort when developing a new aircraft. It is unnecessary to build physical mockups or expensive prototypes thanks to CAD. A prototype design & engineering expert may be required for certain parts of an aircraft.

3D Printing

In the aerospace industry, additive manufacturing has played a significant role in developing flight vehicles. The aerospace industry will spend $3 billion on additive manufacturing or 3D printing in 2022. A large portion of the growth is due to the growing demand for lightweight engine parts.

It encompasses all aerial vehicles, such as small jets and drones, as well as commercial aircraft and massive jet airliners. Small companies developing and selling drones will find 3D printing equipment to be cost effective in the prototyping phase. They can create a full working version of a UAV just using a 3D printer.

CAD & Additive Manufacturing Services

The fields of additive manufacturing and computer aided design are inextricably linked. In contrast to the former, which can be used independently as design software, the latter requires 3D models before it can be printed. The 3D printer manufactures the object created by CAD software.

High demand items for 3D printers in the aerospace industry include mounting brackets, fixtures, and jigs, as well as surrogate parts. Detailed prototypes are rare, but they do exist, mainly for commercially-sold drones since they usually require minimal heavy-duty materials and are usually light.

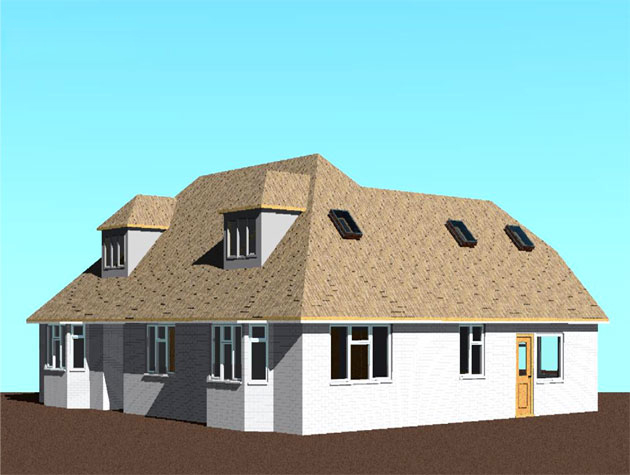

Drafting

In drafting, the goal is to create an abstract representation of what the aircraft will look like. Based on vehicle data sets, aerospace engineers build a three-dimensional model using CAD software. Models or mock ups are not needed because of this process. After the virtual model has been created, aerospace engineers can verify and improve the layout of the design. As of this point in development, the model needs to be detailed further, including electric subsystems and engine schematics.

Accuracy

If multiple companies are involved in the development and aerospace engineering teams at different locations, accuracy depends on enhanced communication and efficient collaboration.

In this way, the design cycle can be reduced, and the team can move forward with confidence to reach the next milestone.

Performance, stability, and maneuverability of the finished model are evaluated through countless simulation procedures. Depending on the type of analysis, aerospace engineers use different simulation parameters.

To get online demonstration, watch the following video tutorial.

Video Source: DarkAero, Inc

You have to maintain a near obsessive level of accuracy since the model will serve as the foundation for the actual aircraft. Each step of the design process is performed with precision to the tiniest details.

The importance of accuracy, even in prototyped parts, is paramount in an industry that operates within an immeasurable margin of error. CAD models are more accurate than printed objects. The most viable solution is to use 3D printing when traditional prototyping cannot keep up with the speed of development.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !