Designing a Car Chassis with Revit

Tweet

Designing a car chassis is a complex process that requires precision, creativity, and a robust understanding of engineering principles. Revit, primarily known for its capabilities in architecture, engineering, and construction, is not typically associated with automotive design.

However, with its powerful modeling tools and parametric design capabilities, Revit can be a valuable tool for creating detailed and accurate car chassis designs.

Understanding the Car Chassis

A car chassis serves as the backbone of a vehicle, providing the necessary structural support and housing various components such as the engine, transmission, and suspension. It must be designed to withstand various stresses and strains while ensuring safety, performance, and durability. Key considerations in chassis design include material selection, weight distribution, rigidity, and ease of manufacturing.

Setting Up Revit for Automotive Design

Before diving into the design process, it's essential to configure Revit for automotive design. This involves customizing the user interface, setting up the project environment, and importing any necessary reference materials.

Customizing the User Interface

Revit's default interface is tailored for building design, so some adjustments are necessary for automotive projects. Customize toolbars and palettes to prioritize modeling tools, parametric families, and materials suitable for automotive applications. Setting up keyboard shortcuts for frequently used commands can also streamline the workflow.

Setting Up the Project Environment

Creating a new project template specific to automotive design is crucial. This template should include predefined views, families, and materials that align with automotive standards. Additionally, setting up a coordinate system that reflects the car's dimensions and orientation ensures accuracy in the design process.

Importing Reference Materials

Having accurate reference materials, such as blueprints or CAD models of existing car chassis, is invaluable. These references provide a starting point and help maintain consistency and accuracy. Revit allows importing various file formats, including DWG and DXF, which can be used as underlays or converted into Revit families.

Designing the Car Chassis

With the project environment set up, the next step is to start designing the car chassis. This process can be broken down into several stages: conceptual design, detailed modeling, and analysis.

Conceptual Design

The conceptual design phase involves creating a basic outline of the car chassis. Start by sketching the overall shape and dimensions using Revit's modeling tools. This stage focuses on establishing the primary geometry and layout without delving into intricate details.

1. Create a Reference Plane: Establish reference planes to define the key sections of the chassis, such as the front, middle, and rear sections.

2. Sketch the Outline: Use the extrusion tool to create a basic outline of the chassis. Pay attention to proportions and ensure the design accommodates all necessary components.

3. Define Key Points: Identify and mark critical points where major components will be mounted, such as the engine, suspension, and axles.

Detailed Modeling

Once the conceptual design is in place, the next step is to add details and refine the model. This involves creating parametric families for various chassis components, such as beams, brackets, and joints.

1. Create Parametric Families: Design parametric families for different chassis elements. These families should be adjustable to accommodate design changes without requiring extensive rework.

2. Assemble the Chassis: Using the parametric families, assemble the chassis model. Pay attention to connections and joints, ensuring they are realistic and functional.

3. Add Reinforcements: Identify areas that require additional reinforcement and add necessary elements to enhance rigidity and durability.

Analysis

After completing the detailed model, it's essential to analyze the chassis to ensure it meets all performance and safety requirements. Revit integrates with various analysis tools, allowing for comprehensive structural analysis.

1. Structural Analysis: Perform a structural analysis to evaluate the chassis's strength and rigidity. Identify any potential weak points and make necessary adjustments.

2. Material Analysis: Assess the materials used in the chassis design. Ensure they meet the required standards for strength, weight, and durability.

3. Simulation: Run simulations to test the chassis under different conditions, such as load-bearing and impact scenarios. Use the results to refine the design and enhance performance.

Finalizing the Design

With the analysis complete, the final steps involve reviewing the design, making any necessary adjustments, and preparing the model for production.

Review and Adjustments

Conduct a thorough review of the chassis design, focusing on both functionality and aesthetics. Involve stakeholders, including engineers and designers, to gather feedback and make necessary adjustments.

1. Design Review: Schedule a design review meeting with the team to discuss the chassis model. Address any concerns and incorporate feedback into the design.

2. Adjustments: Make final adjustments based on the review. Ensure all components fit together seamlessly and meet the design specifications.

Preparing for Production

Once the design is finalized, prepare the model for production. This involves creating detailed drawings and exporting the model in formats suitable for manufacturing.

1. Create Detailed Drawings: Generate detailed drawings of the chassis, including dimensions, materials, and assembly instructions. Ensure the drawings are clear and comprehensive.

2. Export the Model: Export the chassis model in formats compatible with manufacturing processes, such as STL or STEP files. Ensure the exported files maintain the accuracy and integrity of the design.

To get online demonstration, watch the following video tutorial.

Video Source: Balkan Architect

Conclusion

Designing a car chassis with Revit requires a blend of creativity, technical expertise, and a thorough understanding of automotive engineering principles. While Revit is traditionally used for building design, its powerful modeling tools and parametric capabilities make it a viable option for automotive projects.

REVIT VEHICLE FAMILIES DOWNLOAD

By customizing the software, following a structured design process, and leveraging analysis tools, you can create detailed and accurate car chassis designs that meet all performance and safety requirements. Embrace the potential of Revit for automotive design and unlock new possibilities in your engineering projects.

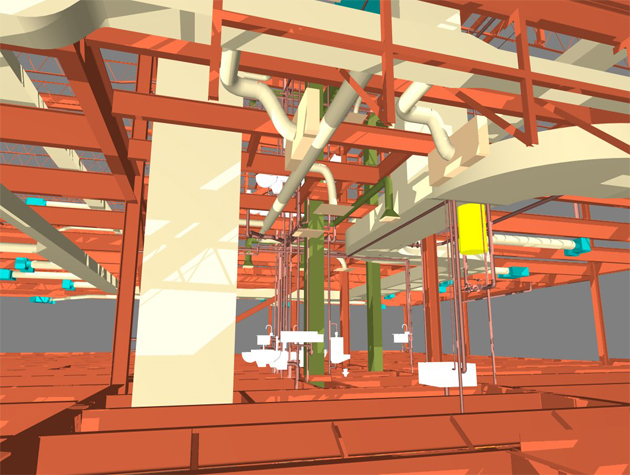

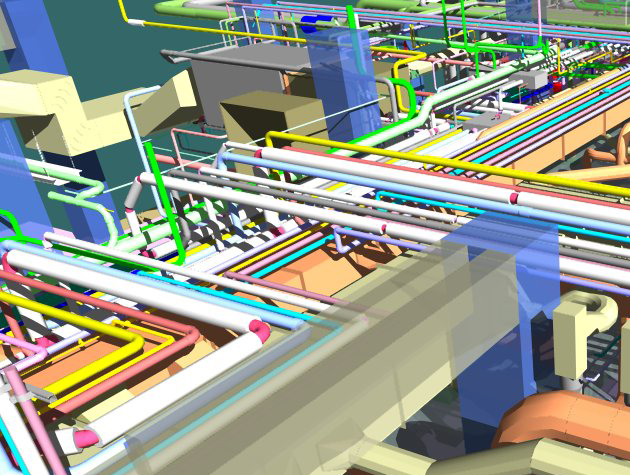

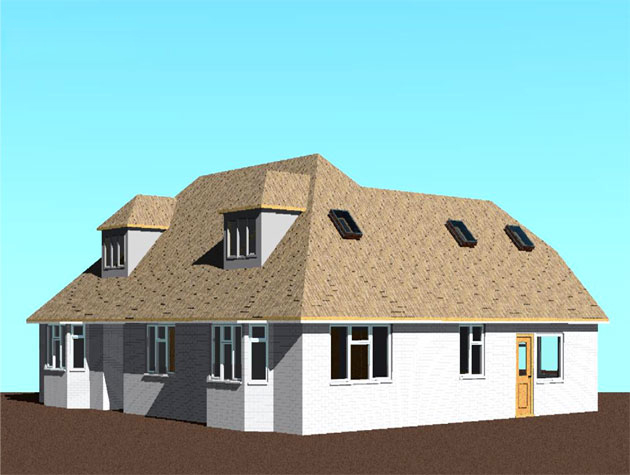

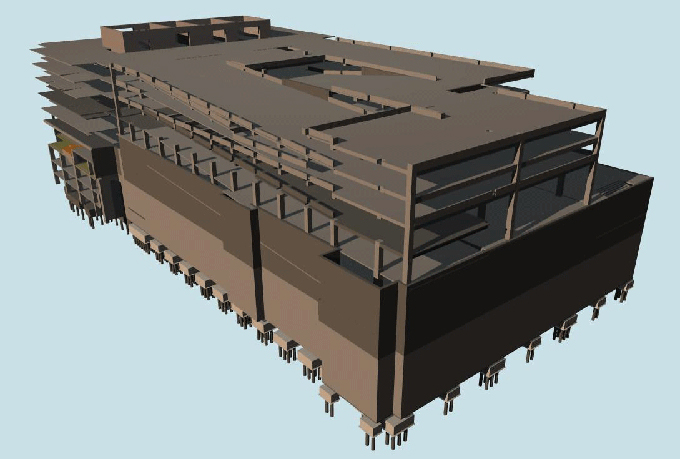

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !