Precast Automation in Revit

Tweet

Revit 2021 has been discharged two months back and there's one new lace tab that advanced among the out-of-the-container highlights: Precast. We began our excursion to finding and conveying to clients a robotized procedure for taking care of basic precast components from displaying to creation just about three years back.

From that point forward, we discharged a few new highlights and upgrades dependent on the criticism gathered from the designing and manufacture networks. And furthermore since the time at that point, we've been working intimately with innovation accomplices in characterizing Revit as an adaptable and adjustable stage for the universe of precast cement, to help the bespoke business requests.

We should examine the consequences of our joined endeavors and see what the visionary and creative organizations working in this space need to share, subsequent to embracing the Revit-based advancements.

Kerkstra Precast: Kerkstra Precast is a main precast maker in the US that creates both compositional and basic precasts. They as of late moved from 2D AutoCAD to BIM and have seen effective business results as of now. They use EDGE^R programming, given by PTAC Consulting Engineers, an Autodesk Industry Partner which is based on the head of Revit.

What is one of a kind about the EDGE^R arrangement is that it is BIM-based so precast makers can facilitate their plan with the designers and architects while computerizing the creation expectations, all on a similar stage. One critical advantage is seeing a decrease in mistakes that may occur underway or on the place of work.

They are currently investigating the utilization of BIM prior in the venture to take into account practically continuous cost following item and material departures, which helps Kerkstra better comprehend and depict cost effects of configuration changes or alternatives.

It takes a social move anyway to receive BIM. For instance, Kerkstra is presently utilizing Autodesk Revit to streamline the formwork to lessen waste and accelerate creation, yet that wasn't the standard. They are likewise beginning to investigate model information from Revit, by means of Unitechnik group documents, to drive the water-solvent bed plotter.

This dispenses with the occasions when creation bed faculty need to take a gander at conventional reports and permits them to concentrate on the creation procedure all the more eagerly. Moreover, the utilization of this innovation in the processing plant diminishes blunders and accomplishes a superior generally speaking quality while lessening the exertion for the workforce.

Beton-Stahl: Beton-Stahl is an auxiliary building firm headquartered in Hudson, Wisconsin. They convey auxiliary designing and drafting administrations for both steel and solid tasks. Being established as of late in 2012, they have developed rapidly by surpassing their clients' desires. "To be an important accomplice to our customers, we should have the option to change from plan to creation rapidly." says President, Corey Leith.

Some portion of their development procedure has been to receive the most recent innovation. Utilizing the EDGE^ arrangement, given via Autodesk Industry Partner PTAC, has helped them make the jump to BIM and convey more tasks, having point by point more than 30 precast undertakings utilizing BIM. A key advantage for utilizing BIM is the information wealth of the subsequent 3D model. EDGE^ was a key driver for Beton-Stahl's transition to Revit to do BIM-based precast itemizing, says Mr. Leith. The principal driver is the volume of data they can extricate from the model for their customers without included expenses.

Superior Walls of America: Superior Walls of America is an innovator in custom precast cement protected divider boards with licensees situated in the US and in Canada. These items are made in quality-controlled manufacturing plants that consider brief particulars and dimensional exactness while guaranteeing the most excellent accuracy and consistency.

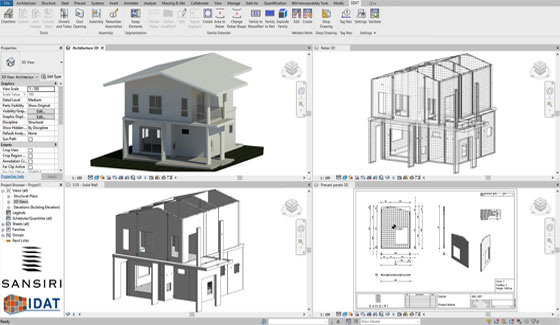

They as of late moved to Revit for precast specifying, alongside industry accomplice IDAT's Revit Precast application. Having the info consistently cutting-edge and facilitated with all gatherings occupied with the task is basic, and this is the reason they see the Revit model as the single wellspring of truth.

Every Superior Walls venture is hand crafted to meet careful auxiliary plan details and to improve the vitality proficiency of the structures. Take for instance the Xi Wall, thermally disengaged and protected from the outside components, so remarkably superior to traditional establishment frameworks. This establishment divider is solidly poured with high-quality cement for strong basic respectability and strengthened with steel rebar and polypropylene strands. Ordinarily, it is utilized for the storm cellars of wood-based superstructures.

Through the CAM interface, the walls are traded to the Palletizer, which sorts out the position of the precast boards on the creation beds of the industrial facility and enables Superior Walls to enhance their creation for different activities without a moment's delay, something that before was difficult to them.

Utilizing a similar programming, they will have the option to improve the manufacture exactness by going to a laser projection framework to speak to the board format on the creation table and to send out the rebar detail to a rebar twisting and slicing machine through a similar CAM interface. At last, they anticipate improving much more the quality affirmation process, by utilizing increased reality.

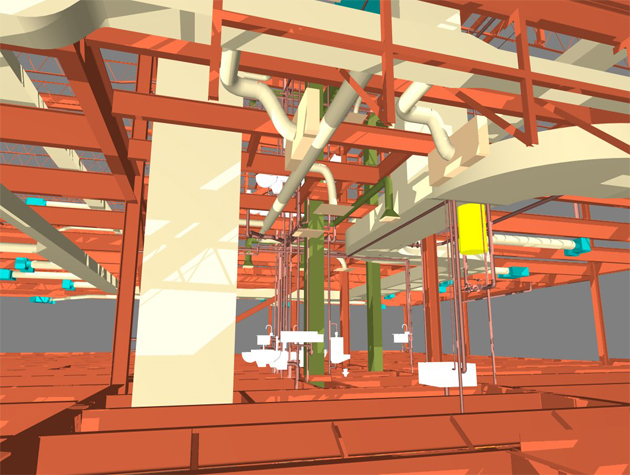

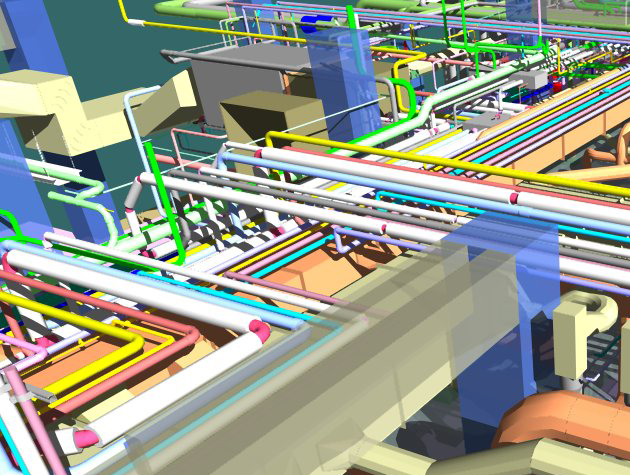

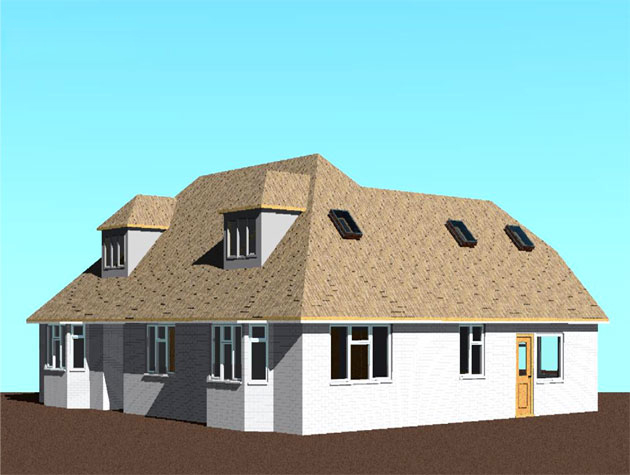

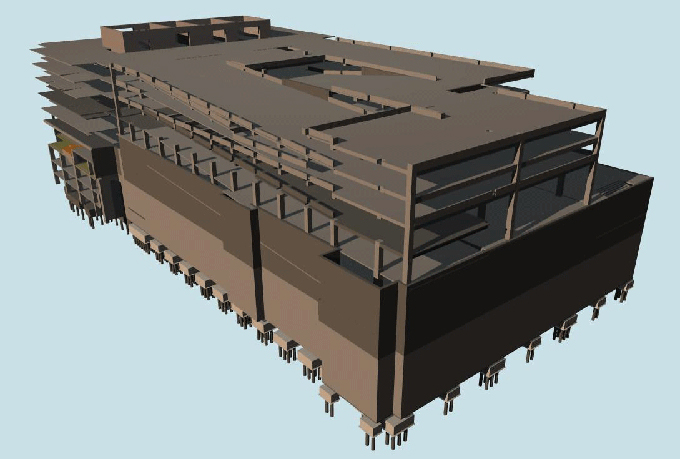

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !