The Impact of Robotization on Bim Outflow

Tweet

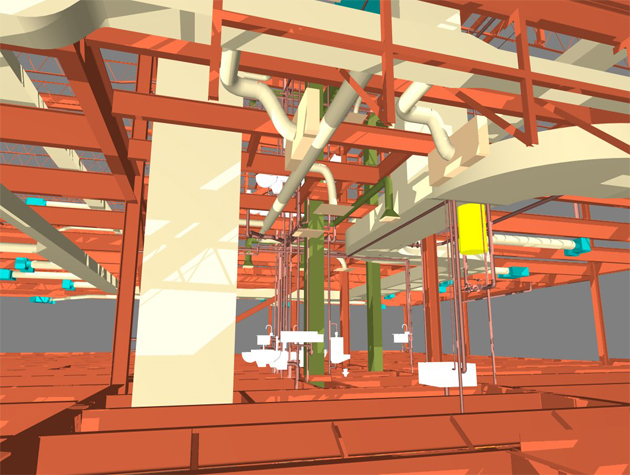

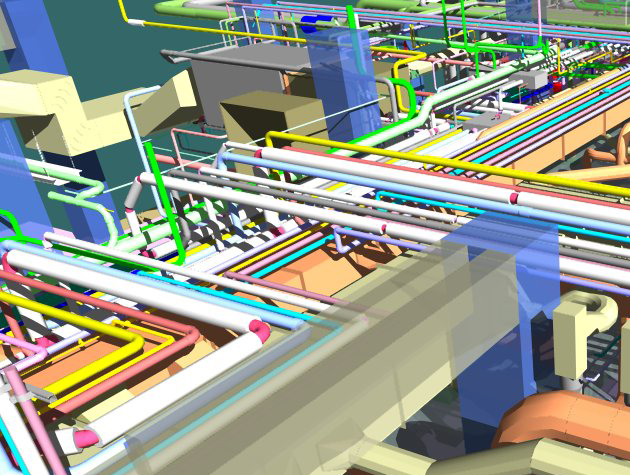

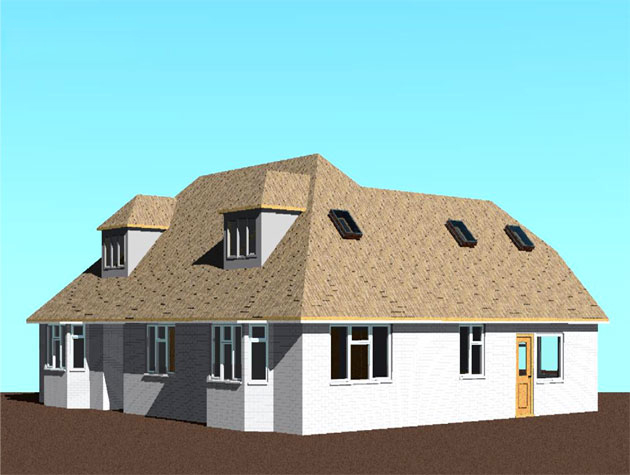

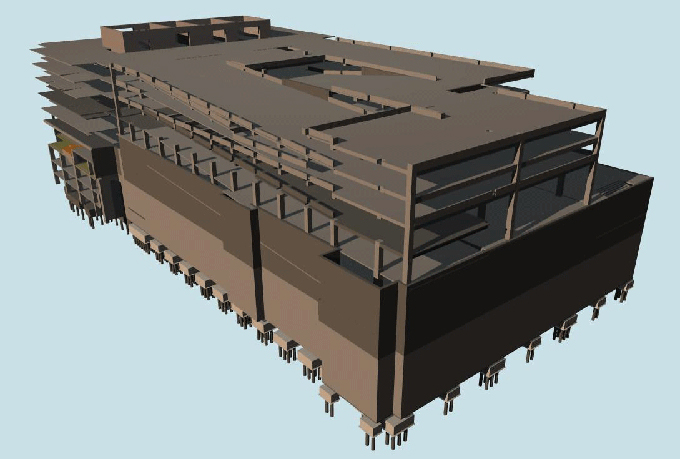

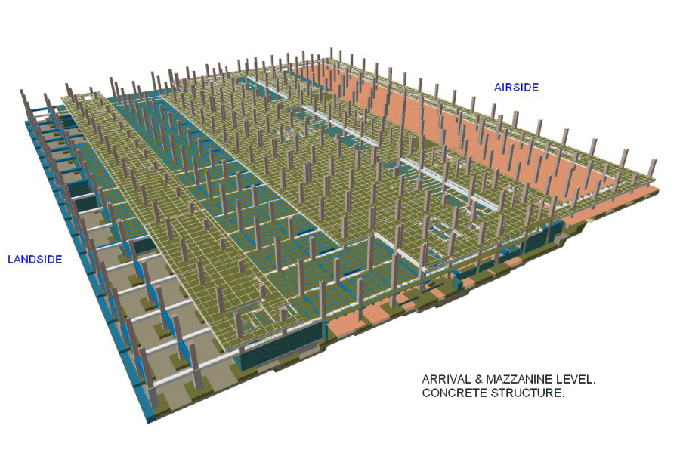

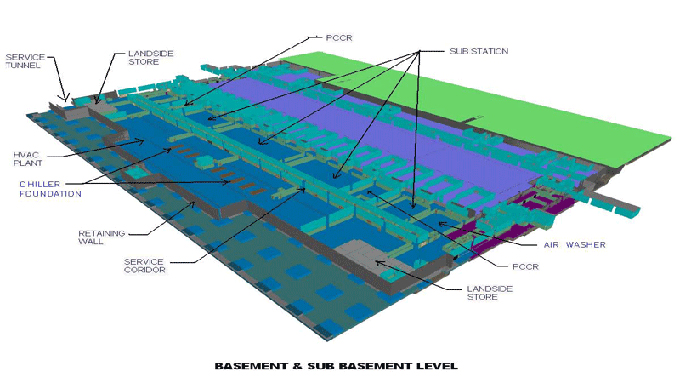

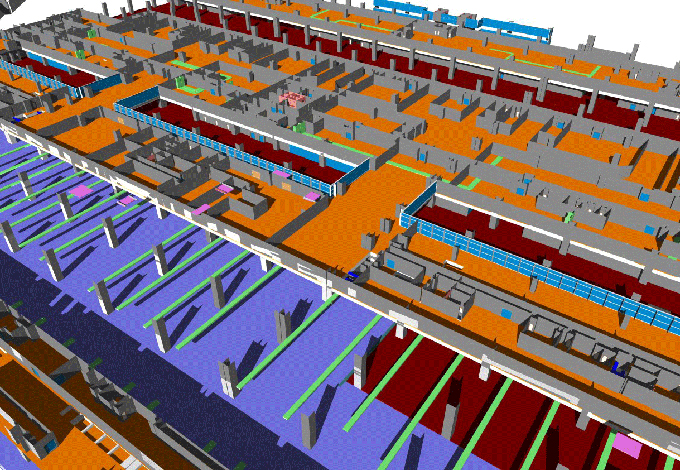

The architecture, engineering and construction (AEC) industries has greatly benefited by the introduction of BIM (Building Information Modeling). Digital, 3D building designs and construction plans are used by BIM to guide monitor construction processes and has impacted the AEC industries vastly. Not only by providing visualization but BIM has also helped significantly with coordination between different sectors by providing accurate, up-to-date information about the project.

The introduction of robotics will be another exciting addition to the industry. Both, BIM and robotics can function together. While robotics will take care of the dangerous routine tasks and in turn also increase safety and performance, BIM could be useful for acting as a map for the robot working on site.

Time and money, both can be saved by using robots to perform the dangerous manual tasks. With minimal assistance and supervision, the requirement for a big team of people will also reduce. Robotization will minimize expensive errors as well as reduce the possibilities of fatal accidents. Even during harsh conditions robots can be used. Robots are used now as safety inspector by the AEC industries.

Given below is a list of ways by which robotization will help accelerate and improve BIM workflow:

- 3D printing full structures: There are robots for 3D print building models along with robots which can print 3D prints of actual metal structures.

- Assisting with dangerous tasks: Robots can be of immense help when it comes to carrying heavy loads, digging, drilling, cutting, parts assembly and other risky tasks which are unavoidable.

- 3D printing complex components: There are robots designed for 3D print a portion of a building with great speed and accuracy than current manufacturing process.

- Help achieve sustainability: Some robots are specifically designed to save energy. They constantly monitor building?s temperature, lighting, air quality, etc.

Here is a list of BIM-based robots today:

Robotics and BIM together not just helped with coordinating job but also was of great help to store database for construction robots to use. Stated below are such examples:

- The Husky A200: The Husky A200 mobile robot by Fraunhofer Italia assists the logistics on construction sites. The robot helps in transporting tools from one location to another. It has sensors and lasers which it uses to follow workers when required. It can also adapt to the environment and detect obstacles.

- Hyundai?s Elevate: It is one of the most recent innovations, it is a collaboration product of Hyundai and Autodesk. In 2019 Elevate is an Ultimate mobility vehicle (UVM) which can move using both wheels and four legs. Due to its agile anatomy, the robot can navigate around any terrain and can withstand the harshest of weather conditions. Other than helping people with disabilities to move, it can also be used for construction, rural exploration and disaster rescue.

- The Hilti Jaibot: Hilti which is one of the leaders in construction tool manufacturing released its first robot in 2020- naming it the Jaibot. Jaibot is a semi-automatic machine which can assist with the task of drilling. It comes with great speed, accuracy, along with safety for plumbers, electricians, and others who might use the robot. It is easy to use and its cordless feature helps it be flexible. The use of Jaibot can made overhead drilling a less strenuous job than it is. It can also work for up to 8 hours without recharging it.

- The GE Tunnel-Digging Robot: This machine was created by Penn State University and General Electric Company with a funding by DARPA. The design is inspired from earthworm and therefore provides the robot with both agility and speed. With the robot digging a 100m tunnel with a diameter of 19 cm can be completed in 15 minutes. It can also penetrate through extremely compact soil by exerting strong pressure during the drill. It can be used for infrastructure inspection and repair, soil inspection, and more. It does not even require heavy and bulky digging equipment.

- The MX3D Printer Robot: MX3D enables users to 3D print large objects in metal. With a 3D printing robot, an entire bridge was created. After thorough planning for about 18 months, the bridge was successfully printed in metal using robotic printing arms.

The Future with Robots

Robots will play a major role in the AEC industries with the rapid technological growth. Even though robots are not yet equipped to build structures according to required needs but with time and right growth even that will be possible. Robots have a high chance of replacing humans in field that require mathematical calculations with their super-fast speed and accuracy.

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !