Usage of BIM to promote and facilitate Prefabrication

Tweet

Definition: The term 'prefabrication' describes assemblies that are manufactured under factory conditions and then transported to construction sites for incorporation into building or civil engineering works.

Offsite construction is closely related, but a little different. The term involves the broader aspect of planning and manufacturing buildings in another place.

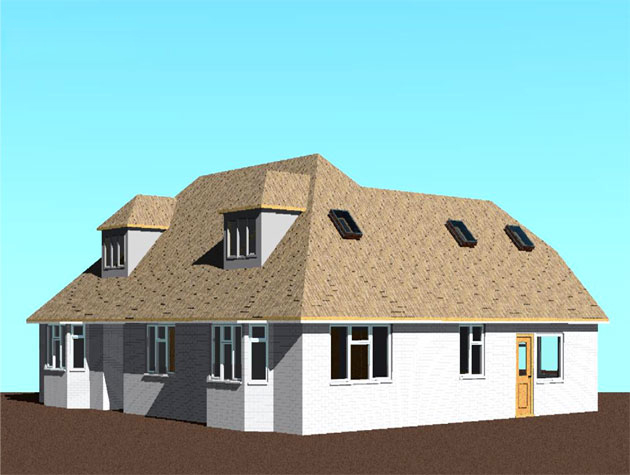

Offsite construction is agnostic as to how the components produced there eventually come together. They may be modular or manufactured. For instance, manufactured housing refers to homes built elsewhere and delivered to a site.

Modular housing refers to pieces of buildings manufactured offsite, then delivered for final installation and connection. Prefabrication can refer to both of these, as well as the manufacture of repeatable components (steel and timber frames or glass panels, for instance).

Benefits of Prefabrication

Prefabricated construction is becoming more common, improving in quality and has become available in a variety of budgets. Despite the perception of prefabrication, there are numerous benefits to this type of construction. Some of them are specified below:

Eco-Friendly

Modular construction is often commended for energy efficiency and sustainable construction. Traditional construction methods require extra materials that lead to increased waste. However, since prefabricated sub-assemblies are constructed in a factory, extra materials can be recycled in-house. This is a considerable improvement over sending waste directly to a landfill from a traditional construction site.

Financial Savings

One of the greatest advantages of prefabricated construction would be financial savings. Although the perception of custom-made pieces may seem expensive, with prefabricated or modular construction, this is not the case. Modular construction targets all budgets and price points, creating an affordable option. Prefabrication manufacturers often receive bulk discounts from material suppliers which then trickles down to the cost of a construction project.

Consistent Quality

Since prefabricated construction occurs in a controlled manufacturing environment and follows specified standards, the sub-assemblies of the structure will be built to a uniform quality. Construction site-built structures are dependent upon varying skill levels and the schedules of independent contractors. These all contribute to the craftsmanship and overall quality of given structure.

Leveraging BIM in the prefabrication space

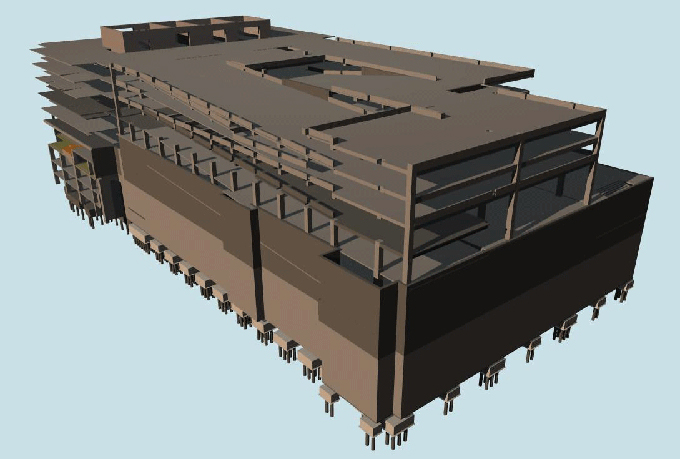

Today, 72% of firms are thought to be using BIM technologies. By offering "visibility and transparency during a project to make sure things are moving on the schedule that's been committed to and within the estimated budget that's been put forth," BIM tools can offer significant ROI for architecture, engineering and construction (AEC) professionals.

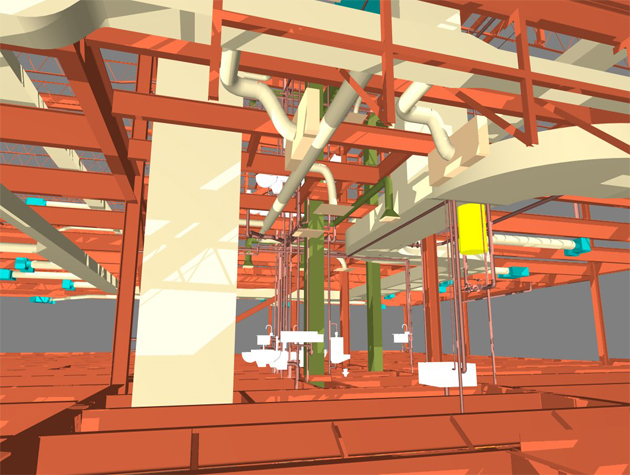

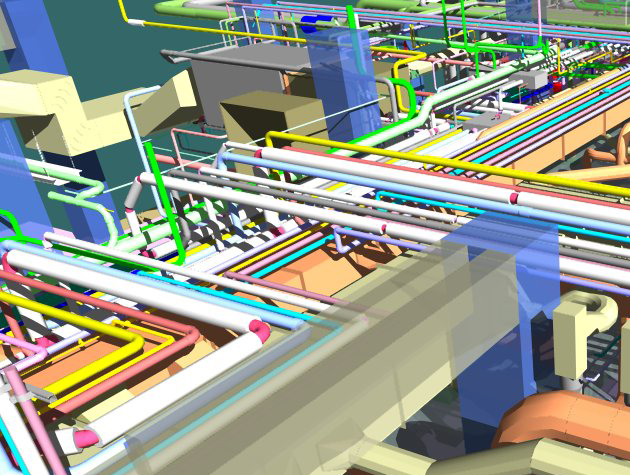

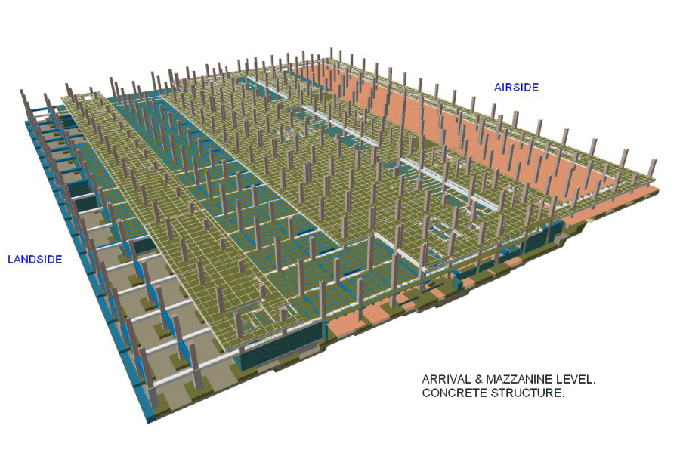

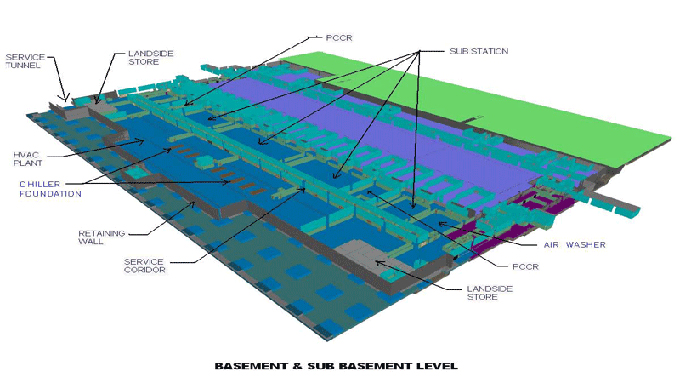

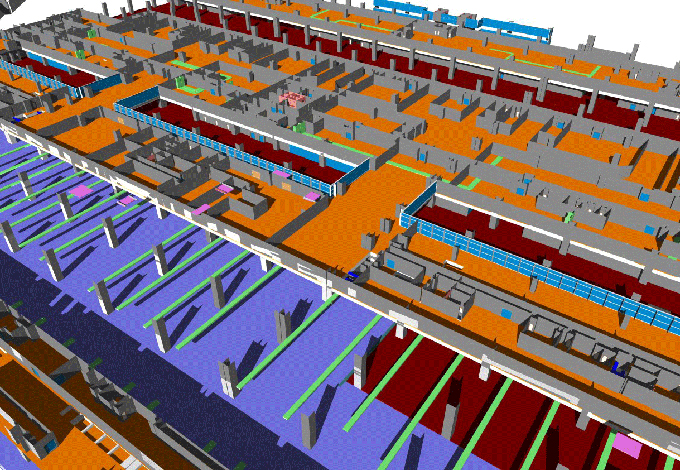

In addition to the base-level geometry of a structure, BIM includes spatial relationships; mechanical, electric and plumbing (MEP) components and the quantities and cost estimates for the building materials that will be needed. And any time a change is made, related objects are updated along with it, all in a centralized model that every team member involved on the project can access.

Having a comprehensive, digital picture of a project can help the players involved understand what resources are needed and when, and minimize the risk of over- or under-estimating the time and money the project will require in prefab and modular construction, assembly requirements can change as the piece, panel or module design is tweaked. Once the design is finalized, BIM can be useful in creating visual-based manuals.

Final Thoughts

The use of BIM software technology has facilitated the prefabrication coordination process and has increased the potential for prefabrication on multiple levels. Prefabricated MEP sub-assemblies have become a safer and more predictable option since the rise in the usage of BIM coordination.

Designing in the prefabrication elements of the building into the BIM model has many advantages. It smoothens and speeds up the approvals processes as these are much simplified.

Image Courtesy: bimservicesindia.com

Gallery

Feel free to contact us for BIM requirements. One of our representative will respond you within 24 Hours. Send us your projects requirement today and grow your project.

Explore More !